We improve

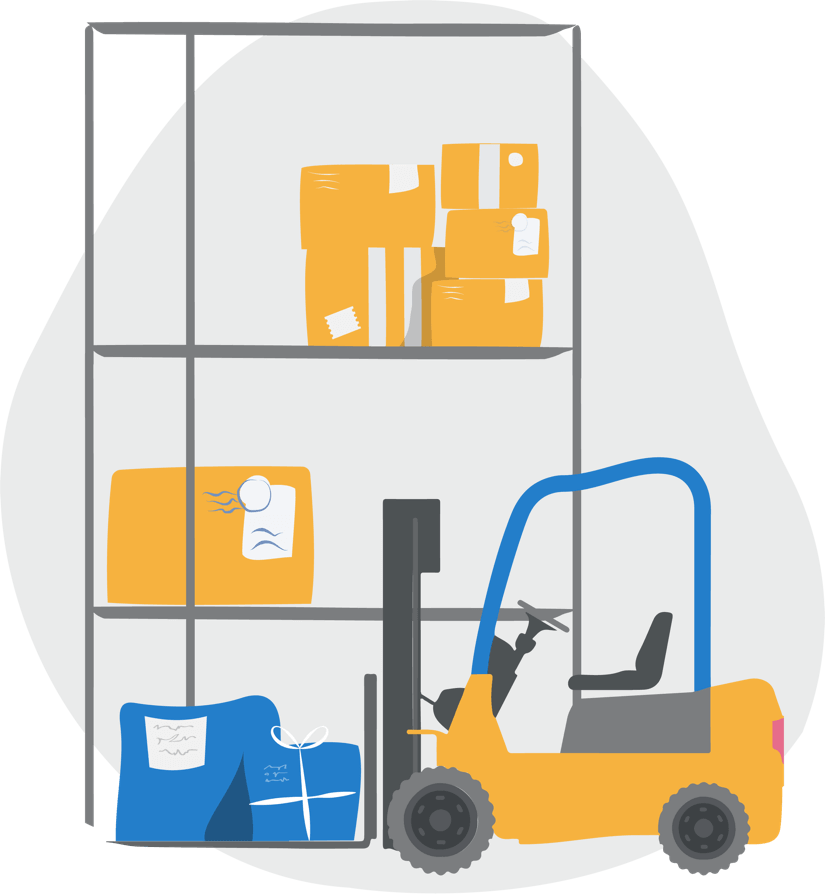

Inbound

Receive products on the receipt zone. Generate unique barcodes if needed. Bring them to a pick or bulk location, or a pick/drop zone.

Stock balance

In case of stock differences in the received stock, an order is automatically sent to a lost/found location.

Data

Upload all imaginable file formats. From Excel and web forms to common standards such as EDI, Edifact XML and X12. The system recognises, processes and validates data fully automatically.

Supplier performance

Automatically perform random checks on incoming goods depending on the historical performance of shippers and forwarders.

Returns

Returns are automatically logged in. Gain insight into the defects per customer, the reason for return and whether they can be returned. Bring returns back in stock or make them ready for sale first. Destroy defects or dispose of them and claim them immediately.

Cross docking

Streamline receipts and dispatches. Send incoming goods directly to the dispatching zone for faster dispatch of orders.

Smart warehousing

Receive and evaluate suggestions to make processes more efficient. To combine activities (batch picking) or eliminate unnecessary activities for example. New products will be immediately recognised upon entry.

Efficiency

Save intermediate steps. Send a product directly from the unloading dock to a pick location when a product is out of stock. Assign popular products to easily accessible locations using ABC classifications. Classify based on pick frequency or future demand.

Storage types

Establish rules regarding products that absolutely must not be placed in the same space and receive storage advice based on weight and volume. Take into account the maximum number of kilos a location is allowed to carry. Store on the basis of customer-specific stock or factors such as value, perishability and ADR.